Prefabrication has gained significant popularity in the construction industry due to its numerous benefits, including improved efficiency, cost savings, and enhanced project quality. As a contractor, setting up a prefabrication shop can be a game-changer for your business. We have developed a comprehensive guide to help contractors navigate the process of establishing a successful prefabrication shop. Let’s check the steps!

8 steps for Setting up a Prefabrication Shop

Step 1: Define Your Goals and Objectives

Begin by clearly defining your goals and objectives for establishing a prefabrication shop. Determine the types of components you intend to fabricate off-site, the scale of projects you aim to undertake, and the specific benefits you hope to achieve, such as cost savings, accelerated project timelines, or improved quality control. These goals will guide your decision-making process throughout the setup phase.

Step 2: Identify Suitable Facilities

Evaluate your existing facilities or identify a new space suitable for your prefabrication shop. Look for a location that offers ample space for component assembly, storage of materials, and equipment. You should consider factors such as accessibility, proximity to your project sites, and any zoning or permitting requirements that may apply.

Step 3: Select Appropriate Equipment

Investing in the right equipment is crucial for the success of your prefabrication shop. Consider the specific needs of your projects and choose equipment accordingly. Common equipment for prefabrication includes cutting and shaping tools, welding and joining equipment, assembly stations, material handling tools, and quality control devices. The key to success is selecting reliable, high-quality equipment that can handle the volume and complexity of your fabrication requirements.

Step 4: Build a Skilled Team

A skilled and knowledgeable workforce is essential for running a successful prefabrication shop. Assess your current workforce and identify any gaps in expertise. Hire or train employees who have experience in prefabrication techniques and are well-versed in working with the chosen equipment. Encourage ongoing professional development and invest in training programs to ensure your team stays up to date with the latest industry advancements.

Step 5: Implement Efficient Workflows:

Streamlined workflows and standard operating procedures (SOPs) are crucial to maximize efficiency and productivity in your prefabrication shop. You should clearly define each step of the fabrication process, from receiving and inspecting materials to assembly, quality control, and packaging for transportation. Optimize the flow of materials, tools, and personnel to minimize downtime and eliminate bottlenecks.

Step 6: Embrace Technology and Automation:

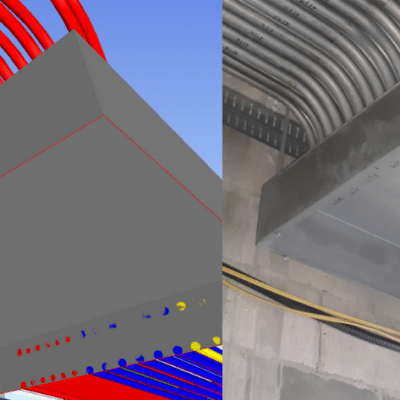

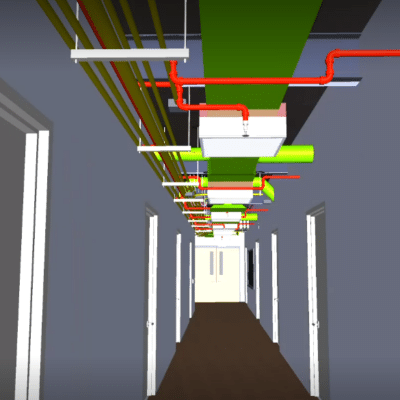

Use technology and automation to enhance the efficiency of your prefabrication processes. Explore software solutions that can aid in design, project management, and BIM integration. It’s crucial to highlight that adopting a higher level of BIM is no longer just an advantage; it has become essential. LOD 400 BIM models are necessary to ensure accuracy and efficiency in off-site fabrication. Furthermore, automated machinery, such as CNC machines or robotic systems, can significantly increase precision and speed up fabrication while reducing errors.

In a recent visit to McClure Company’s Fabshop, one of our clients, they emphasized the significance of BIM in their operations. Colton Forbes, the Fabrication/Quality Control Manager at McClure Company, highlighted:

“The key for a successful and efficient fabrication process starts with detail and accurate information coming into the Fabshop whether that pertains to spool drawings, spools and materials, having all that information correct upfront is a huge factor in overall success.”

Step 7: Ensure Quality Control:

Maintaining rigorous quality control measures is crucial to delivering high-quality prefabricated components. Establish quality control checkpoints throughout the fabrication process to ensure adherence to specifications, standards, and project requirements. Implement thorough inspection protocols, testing procedures, and documentation processes to guarantee the reliability and durability of your prefabricated products.

Step 8: Monitor and Improve:

Continuously monitor and evaluate the performance of your prefabrication shop. Analyze key metrics such as productivity, cost savings, and customer satisfaction to identify areas for improvement. Regularly review your workflows, equipment, and training programs to ensure they align with industry best practices and evolving market demands.

Final thoughts

Following all these steps to set up a prefabrication shop is essential for overall project success. However, as a BIM company, we need to emphasize the importance of using true LOD 400 models to avoid surprises once you are installing the prefabricated items.

We have helped hundreds of contractors gain tremendous efficiencies taking care of their VDC needs for trades coordination and prefabrication. Most importantly, they have gained a significant competitive advantage by prefabricating components off-site and recognizing the importance of these steps for success. Our BIM/VDC services for prefab & installation are focused on making your life easier on the shop and in the field– reach out to us now!