In Part II of ENG’s Chronicles: Turning Data Gaps into Digital Gold Part, we continue the detailed exploration of a laser scanning project for a large-scale utility plant on the East Coast. The central utility plant spans nearly 500,000 square feet. To digitally capture it, the ENG Laser Scanning and Scan-to-BIM team conducted almost 4,500 scans and set 155 survey control points across seven levels. These figures underscore the project’s vast scale and complexity, where each square foot posed unique challenges and demanded meticulous planning and precision.

Led by Mariana Jimenez, Director of Laser Scanning and Scan-to-BIM Services, ENG’s team encountered logistical and technical hurdles, collaborating with multiple stakeholders while leveraging advanced laser scanning technologies to achieve high-quality results. This article will cover the project’s essential elements: stakeholder alignment, precision scanning strategy and equipment, on-site challenges, and comprehensive deliverables. If you missed Part I, you can catch up here.

Aligning Stakeholders for Scan-to-BIM Success

Executing a project of this magnitude required seamless stakeholder alignment and constant communication among all involved parties. From the start, ENG aligned expectations across all key stakeholders to ensure the project’s scope and budget stayed controlled and achievable. Each stakeholder—from the engineering firm to on-site escorts and the dedicated scanning crew—played a vital role in ensuring efficient operations and facilitating the laser scanning for construction.

Key Stakeholders:

- ENG’s Client: The engineering firm overseeing project execution.

- Client’s Client: The building owner would be the ultimate end user of the captured data.

- On-Site Contact: A team coordinating with our scanning crew daily to facilitate access and communication.

- Laser Scanning Crew: Our skilled partners conducted on-the-ground scanning.

- Modeling Team: ENG’s BIM modelers transform captured data into usable models.

Each group brought unique needs and expectations that required careful management. This alignment enabled all project phases to stay on track and focused on the primary objective: delivering precise, actionable data to guide the facility’s future improvements, maintenance, and operations.

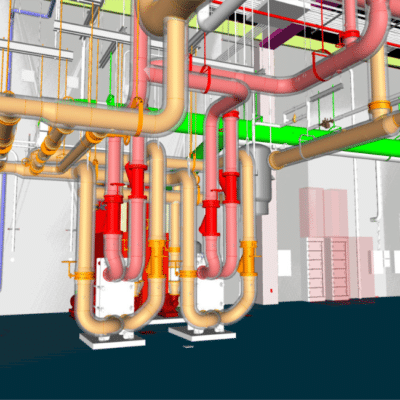

Precision Scanning Strategy and Essential Equipment for Laser Scanning for Construction

A large-scale project like this one demanded a scanning strategy as precise as the technology used. Consequently, ENG’s team began the scanning process with a structured plan. Furthermore, they started with the plant’s exterior, set control around boundaries, and then transitioned inside from the subbasement upward.

“We adapted our strategy as we progressed,” explains Mariana Jimenez. The plant’s intricate layout and dynamic environment made flexibility essential to accurately capturing every critical detail. This flexible strategy allowed us to adjust in real time, optimizing our approach to managing the scope and schedule more effectively.

We planned exterior scans during clear weather to counteract March’s unpredictable weather patterns. Inside the plant, our scanning and survey teams worked closely to cover adjacent areas and maintain data continuity, all while minimizing disruptions to active facility operations.

Essential Equipment for Laser Scanning

In addition to the scanning strategy, only top-quality equipment would suffice for this highly intricate project. We deployed Leica RTC360 terrestrial scanners for high-resolution laser scanning, paired with Trimble Focus 35 and R12i RTK GNSS systems for precise survey control. Strategically placed custom targets ensured accuracy, while “tilt & turn” checkerboard paddles acted as portable aids, ensuring alignment in even the plant’s tightest spaces.

With this combination of top-tier equipment and an adaptive scanning strategy, our team created a clear pathway forward. As a result, we overcame challenges and provided highly accurate as-built models essential for project success.

Overcoming On-Site Obstacles with Adaptive Scanning for Facility Management Data

Working within an operational central utility plant brought unique challenges, even with meticulous planning. Despite thorough preparation, adapting to the realities of the site required ongoing flexibility. “Adaptability was key,” reflects Mariana, “as we had to adjust our approach daily to ensure that every essential detail was captured accurately without disrupting facility operations.”

Key obstacles encountered included:

- Labyrinthine Layout: The plant’s structure, overlapping platforms, tight corridors, and complicated scan path planning required our team to frequently revisit previously scanned areas to ensure all angles were covered.

- Heavy Foot Traffic and Ongoing Construction: With the facility operational and under construction, our team contended with high foot traffic and scaffolding obstacles. “Working around multiple active crews required careful timing,” shares Mariana, “and required phasing our scans to avoid interference.”

- Persistent Flooding in Basements: Flooding in the basements created reflections that compromised scan quality. Thus, the team conducted multiple site visits to mitigate the issue and adjusted the data for accuracy in certain areas.

- Narrow Catwalks and Challenging Access Points: Tight spaces limited scan overlap, complicating consistent control point setup. Our team carefully positioned scans to address this, often repeating efforts to ensure proper registration across levels.

In the face of these challenges, the ENG team’s commitment to quality never wavered. “Each setback was an opportunity to innovate,” Mariana notes. “By adjusting our strategy to address each obstacle, we provided a final product that met the client’s standards for both accuracy and usability.”

Comprehensive Deliverables for Future BIM Modeling and Facility Management

ENG’s Laser Scanning and Scan-to-BIM team prepared an extensive set of deliverables to support future BIM modeling and facility management, including:

- Colored point clouds with control points and 360-degree panoramic views, covering 4,497 scans and photos.

- Systematic file organization and naming convention to ensure usability and seamless tracking.

- The 155 survey control points ensured precision in data alignment and played a crucial role in the registration process.

ENG securely transferred all organized data to the client’s BIM360 hub, ensuring a centralized, accessible location for all stakeholders.

Structured deliverables included:

- 01-RCS (Unified Point Cloud): Essential for Revit modeling, decimated to 5 mm and capped at 15 GB per file.

- 02-LGS (Panoramic Views): Each batch is under 25 GB and optimized for easy access via the TrueView application.

- 03-Survey Reports: PDFs with floor plans marking measured point locations alongside CSV files with point attributes.

- 04-RCP (Recap Files): Supplemental structured point clouds for Autodesk software users.

- 05-Raw Data (RTC360 Files): Various support files for archival purposes.

In the end, thanks to the meticulous organization and robust survey control framework, ENG delivered data that was both accurate and accessible. Ready to support each project phase confidently and ensure the success of future BIM modeling and facility management.

Our journey continues with Part 3, where we explore the next stages of our scan-to-BIM process. Stay tuned!