How do you transform raw scan data into actionable insights when faced with a monumental project and no clear BIM roadmap? For ENG’s Laser Scanning and scan-to-BIM specialist, this challenge was significant. It marked the next step in their journey to digitally reimagine a massive central utility plant on the East Coast. Furthermore, armed with scan data but lacking a BIM execution plan (BEP) or defined standards, the unit needed to act quickly and strategically to bring clarity to the chaos.

In this third installment of ENG’s Chronicles: Turning Data Gaps into Digital Gold, we explore how Mariana Jimenez’s team transformed raw scan data into precise 3D modeling. Along the way, we’ll highlight the core pillars of their success: effective Revit model management, innovative modeling strategies, and the power of automation. These strategies enabled ENG to navigate one of its most complex projects precisely and efficiently.

If you missed the earlier chapters covering the art of estimating and the intricacies of scanning, now’s the perfect time to catch up. Let’s dive into the scan-to-BIM strategy, transforming this project into a digital masterpiece!

Streamlining Revit Coordinates for BIM Success

Managing project coordinates on this scale posed unique challenges. Therefore, Mariana Jimenez led ENG’s BIM experts with a precise and straightforward approach. Without a base coordinate system, level elevation input, or 3D geometry, the crew turned to a grid system as their guide. They designated grid intersection A1 on the Ground Floor as the project origin (0,0,0), aligning it with the software’s internal coordinate system.

Mariana described this setup as ‘simple but essential for minimizing downstream errors.‘ Moreover, ENG’s professionals rotated the first point cloud to match concrete column centerlines with grid intersections to ensure alignment. By doing so, they linked the laser scan data to the digital model using the ‘Origin to Origin’ method, maintaining consistency throughout the process.

Subsequently, ENG implemented several key measures to validate and refine the spatial coordination between the data and the model.

- Verification and Export: The team tested the rotated point cloud against four additional grids, confirming alignment across the building.

- File Stacking: They exported and stacked 25 RCS files in Revit to ensure accurate alignment across all levels.

- Cross-checks in Navisworks: Modeled elements at key building corners were exported in NWC format and loaded into Navisworks alongside the point clouds to confirm consistent alignment.

Frequent collaboration between the scanning and modeling teams was crucial, involving numerous calls to smooth the process. Thus, the experts used strategic planning and survey control to successfully rotate, align, and stack all point clouds. As a result, they established a reliable foundation for managing the project’s 21 Revit models

ENG’s Revit Modeling: A Scalable Approach

Tackling the Central Utility Plant required breaking a complex project into manageable parts, a foundational element of ENG’s strategy. As Mariana Jimenez wisely notes, “You can’t manage what you don’t know.” Guided by this philosophy, the crew divided the project into more than 20 3D models. This deliberate choice streamlined workflows and mitigated risks. Moreover, it ensured clarity and organization.

To support this approach, ENG relied on three fundamental principles:

- Phase Delivery: Delivering the first package early encouraged iterative feedback, which minimized the risk of costly rework.

- Limited Users: Capping the number of modelers per file at six prevented file conflicts and maintained workflow efficiency.

- File Size Management: Keeping files small ensured smooth operations and reduced the likelihood of data corruption.

These measures enabled ENG’s BIM experts to work with agility, iterate quickly, and control scope and schedule.

In addition, consistency across the models was equally critical for maintaining quality. To achieve this, ENG implemented rigorous standards. They established a straightforward naming convention for models and Revit families. They also defined worksets with an optimal level of granularity and aligned template choices early in the process. To further eliminate ambiguity, the team adhered to discipline-specific modeling rules:

- Structural Elements: Floors, equipment pads, platforms, and railings were included in structural models.

- MEP Components: Diffusers, plumbing, and lighting fixtures were assigned to MEP models.

- Architectural Features: Air grills and louvers were categorized within architectural models.

This structured approach reduced errors and ensured the models were precise, efficient, and ready to meet project needs. By blending strategic planning with agile execution, ENG’s innovative Revit modeling strategies provided a strong foundation for success.

Boosting Scan-to-BIM Efficiency with Automation

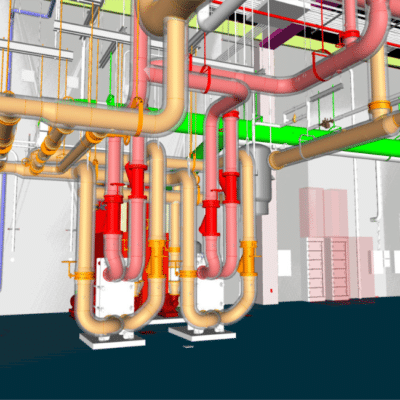

Automation was crucial in transforming laser scan data into precise Revit models. Moreover, it significantly streamlined the workflow and reduced manual effort. ENG’s BIM experts leveraged EdgeWise for this project, a powerful tool designed to accelerate 3D modeling from point clouds. With its advanced algorithms, EdgeWise automatically identified and modeled critical elements such as pipes, walls, and ducts, which proved invaluable for handling exposed MEP systems. As Mariana Jimenez highlights, “When you pair a high-quality point cloud with automation, the results are faster, more accurate, and remarkably efficient.”

The team’s workflow blended automation and refinement to ensure accuracy:

- Automated Extraction: EdgeWise identified elements with a minimum diameter of 2 inches, preventing false positives like railings.

- Refinement and Cleanup: Manual extraction complemented the process, ensuring no missing content.

- Dynamo Integration: Proprietary scripts standardized fittings, converted categories (e.g., pipes to conduits), and assigned workset by discipline.

- Central Model Integration: Clean geometry was imported into discipline-specific Revit models, ready for further refinement and collaboration.

The ENG crew conducted rigorous quality checks throughout the modeling phase to maintain the highest standards. Automated tools like CloudCompare identified 80% of issues, including missing geometry and misalignments. The team exported Revit geometry as STL files and compared them to point clouds in CloudCompare, pinpointing deviations and resolving them directly in Revit.

Meanwhile, manual quality control complemented this automation by catching inconsistencies that tools might miss. Using Navisworks’ appearance profiler, the team detected category misuses, overlapping geometry, and other anomalies. Multiple rounds of refinement and final checks for naming conventions, worksets, and phases ensured that the models met project requirements and exceeded client expectations. Ultimately, this seamless blend of automation and manual oversight allowed ENG to deliver efficient and precise results.

Final Thoughts on Scan-to-BIM Success

In Reality Capture projects, the absence of detailed information and specifications is often the standard—and it’s precisely why ENG is called upon. While precision is a cornerstone of scan-to-BIM processes, true quality extends beyond accuracy. It lies in meeting stakeholder expectations, fulfilling project requirements, and consistently delivering on commitments outlined in the contract. Every project is an opportunity to refine workflows, adapt standards, and create a foundation for more predictable, efficient outcomes in the future.

As we conclude this entry in the blog series ENG’s Chronicles: Turning Data Gaps into Digital Gold, we reflect on the hard work, dedication, and teamwork that turn challenges into accomplishments. Here’s to building the future—one project at a time!