“Digital Twin” has become a buzzword often mentioned alongside Digital Transformation, Industry 4.0, and IoT. But what does Digital Twin really mean, and how can organizations harness its value?

This article explains it clearly, provides examples, and discusses real-world applications, with a special focus on how buildings and facilities can benefit from it.

What Is a Digital Twin?

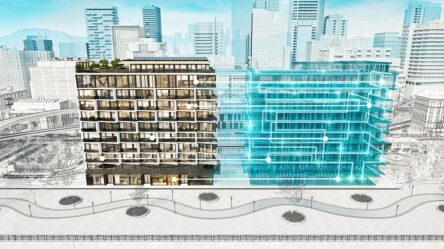

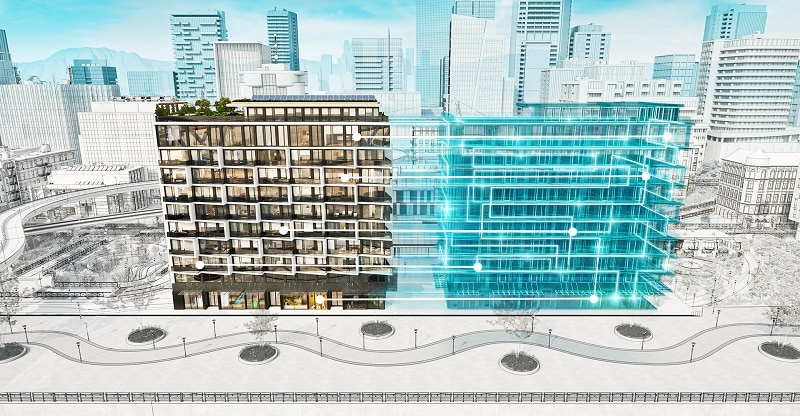

A digital twin is a virtual representation that serves as the real-time digital counterpart of a physical object, system, or process.

In other words, a physical asset is connected to a digital model. Sensors and cloud-based systems feed data into the model, enabling real-time monitoring, predictive analysis, and simulation.

How Does a Digital Twin Work?

Think of a digital twin as a bridge between the physical and the digital world. On one side, you have the physical asset: equipment, a building system, or even an entire facility. Conversely, you have its digital counterpart, constantly updated with real-time data.

This connection is made possible by:

- Sensors and IoT devices capture what’s happening in the real world.

- Cloud platforms process and store information.

- Digital models turn raw data into something you can see, test, and learn from.

Together, this loop allows us to predict failures, run simulations in advance, and make better-informed decisions every day.

Who Invented the Digital Twin?

NASA pioneered the concept of digital twins. They created digital replicas of spacecraft components to monitor equipment beyond physical reach.

NASA describes the approach as:

“Create, test, and build our equipment in a virtual environment. Then tie the physical build back to its digital twin through sensors so that the digital twin contains all the information we could have by inspecting the physical build”

Key takeaway: Digital twins started as a space innovation but have since spread to countless industries.

Digital Twin Examples Across Industries

Digital twins are no longer limited to aerospace. Today, industries worldwide use them to reduce downtime, extend equipment life, and improve efficiency.

Examples:

- Manufacturing: Monitor machines and predict maintenance needs.

- Healthcare: simulate hospital equipment performance.

- Airports: manage passenger flows and facility operations.

- Commercial buildings: integrate HVAC, lighting, and security systems into one digital model.

Example scenario: Imagine a piece of factory equipment equipped with IoT sensors. Data flows into a 3D digital model, where engineers can simulate failures, schedule proactive maintenance, and prevent costly shutdowns.

Benefits of Digital Twins for Buildings and Facilities

For the built environment, digital twins unlock value by bridging design, operations, and maintenance:

- Real-time monitoring: track equipment status and performance.

- Predictive maintenance: anticipate issues before they cause downtime.

- Smarter operations: optimize energy use and space management.

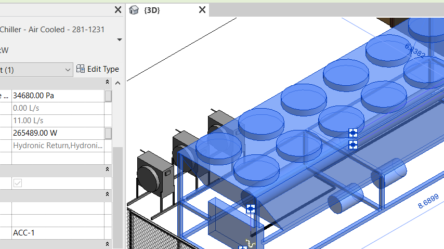

- Data integration: connect BIM models, IoT sensors, and facility systems in one environment.

Key takeaway: Digital twins turn building data into actionable insights, helping teams save time and money.

How YouBIM Makes Digital Twins Accessible

At YouBIM, ENG’s top product, we focus on making digital twins practical for everyday facility management. We help organizations, from offices and airports to manufacturing plants and hospitals, adopt Digital Transformation without steep learning curves.

With YouBIM, facility teams can:

- Access an operational BIM model filled with asset data.

- Integrate sensor information for real-time feedback.

- Support maintenance and operations with a user-friendly interface.

The result? Smarter decisions, fewer surprises, and a digital twin that works for everyone in the organization.

FAQs on Digital Twins

What’s the difference between BIM and a digital twin?

BIM provides a data-rich 3D model at design/construction. A digital twin extends this by syncing real-time data from the physical asset.

Do only large organizations benefit from digital twins?

No. IoT and cloud technology make digital twins increasingly accessible to small and mid-sized organizations.

What problems can a digital twin help prevent?

Unexpected equipment failures, inefficient operations, and costly downtime.

Conclusion

New technology can sometimes feel overwhelming. However, with proper guidance, digital twins can be implemented straightforwardly, enabling entire organizations to reap daily benefits.

Contact us to learn how YouBIM can support your digital transformation journey and enhance your current systems with practical, easy-to-use digital twin solutions.

Florencia Castro

florencia.castro@youbim.com