Few problems in construction are as costly and disruptive as discovering clashes in the field. Whether it’s a duct squeezing past a beam, a cable tray clashing with a sprinkler line, or a pipe encroaching on an access zone, the result is costly rework, added materials, and project delays. However, Clash detection flips that process entirely: problems surface in the model instead of the jobsite allowing predictable, measurable savings.

This article explores clash detection in BIM through a financial lens, how it works, why it drives return on investment (ROI), and why MEP contractors and project owners stand to gain the most.

What Is Clash Detection in BIM?

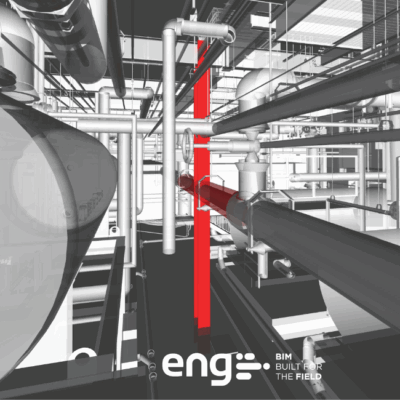

Clash detection identifies conflicts between building systems, structural beams crossing conduits, and HVAC ducts intersecting cable trays inside a 3D BIM model before construction starts. Tools like Navisworks or Revizto scan the model for interferences so teams can resolve them virtually rather than on-site.

Common clashes include:

- Conduit paths crossing mechanical ducts or piping.

- Cable trays conflict with fire protection or structural elements.

- Ductwork colliding with structural beams or soffits

- Insufficient spacing around equipment, violating code or maintenance access requirements

- Overlapping hangers, sleeves, or pipe supports in congested ceiling spaces

Catching these issues during preconstruction avoids expensive redesigns, minimizes field change orders, and reduces stress on crews trying to adapt under pressure.

How Clash Detection Generates ROI

Every clash resolved in the model is a cost avoided on-site. Preventing a conduit rerouting means fewer fittings purchased, fewer labor hours spent, and no downstream trades delayed. When projects prevent dozens or even hundreds of these conflicts, the cumulative effect translates directly into financial gains.

The ROI of clash detection comes from several mechanisms:

- Cost avoidance: Eliminating unplanned rework, extra materials, and overtime labor.

- Schedule reliability: Fewer conflicts mean fewer stop-work moments and earlier turnover.

- Lower risk exposure: Reduced claims, disputes, and safety incidents during installation.

Even without proprietary metrics, industry research is clear: rework can consume 5–15% of total project costs. Clash detection helps significantly reduce that range by resolving conflicts before they escalate.

Quantifying Savings (Without Misleading Claims)

Precise ROI varies by project, but the framework is straightforward:

- If a mid-sized project runs $30M and rework averages 10% of costs, that’s $3M at stake.

- Reducing even a fraction of that through early clash resolution represents meaningful savings, in labor, materials, and schedule impact.

Rather than inflate claims, ENG focuses on documenting outcomes over time. We track clashes identified and resolved during coordination and use those metrics to build accurate benchmarks for owners and contractors evaluating BIM investments.

Why MEP Trades See Strong ROI from Clash Detection

Clash detection creates value for every trade involved in coordinated construction. Still, it’s especially impactful for Mechanical, Plumbing, and Electrical (MEP) systems, where dense layouts and tight sequencing make space a premium.

Here’s why these scopes often see the highest returns:

- Shared spaces, tight tolerances: Electrical conduit, plumbing lines, and ductwork frequently compete for room in ceilings, risers, and mechanical rooms. A single conflict can ripple across multiple trades.

- Complex systems, critical clearances: Whether it’s equipment access for electrical gear, slope requirements for plumbing, or airflow paths for HVAC, coordination errors can lead to major redesigns or safety issues.

- High risk of rework: MEP installations are among the most rework-prone scopes on a job. Catching conflicts before field execution reduces costly adjustments under pressure.

In practice, BIM coordination meetings built around these models are where the value compounds: large conflicts are resolved virtually, priorities are clarified, and responsibilities are assigned, before all materials are ordered or crews mobilize. The result is safer installs, fewer RFIs, and smoother handoffs to owners.

What is Constructability?

In this context, Constructability refers to how easily a design can be built in the field. It considers access, sequencing, tolerances, and real-world site conditions to ensure BIM models are both accurate and buildable

Best Practices to Maximize ROI

To capture the full value of clash detection, teams should consider:

- Integrating trades early: Bring electrical, mechanical, plumbing, and structural models together at project kickoff.

- Automating clash rules: Consistently check clearance zones, equipment spacing, and code compliance.

- Prioritizing high-impact zones: Focus first on risers, data centers, and equipment rooms where space is tight and risks are high.

- Tracking metrics: Monitor clashes resolved, RFIs avoided, and labor hours saved to demonstrate ROI to stakeholders.

- Leveraging field input: Combine modeling expertise with constructability insights from installers to ensure solutions are practical, not just theoretical.

Conclusion: Clash Detection as a Strategic Investment

Clash detection in BIM delivers measurable returns: fewer surprises, smoother schedules, and safer installations. For owners and GCs, coordination transforms from a cost line item into a safeguard against overruns and delays.

ENG continues to refine how we measure and communicate this value, helping teams make confident decisions about adopting BIM and unlocking its full ROI potential.

If you’re looking to reduce rework, improve coordination, and unlock the full ROI of your BIM strategy, let’s talk.

❓ FAQ: Clash Detection in BIM Projects

What is clash detection in BIM?

Clash detection is the process of identifying and resolving spatial conflicts between building systems, such as HVAC, plumbing, electrical, and structure, inside a 3D model before construction begins.

How does clash detection save money?

By catching problems before they happen on-site, clash detection reduces rework, prevents material waste, shortens project timelines, and minimizes risk.

Which trades benefit most from clash detection?

While all trades benefit, MEP systems (mechanical, electrical, plumbing) see the highest ROI due to their density, complexity, and frequent overlap in tight spaces.

What tools are used for clash detection?

Common tools include Navisworks, Revizto, Revit, and Solibri , all of which scan 3D models for spatial conflicts based on pre-set rules.