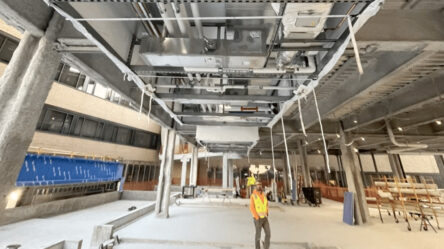

As construction projects grow faster and more prefabrication-driven, many contractors find their internal Building Information Modeling (BIM) coordination teams can’t keep up. Resolving coordination issues and infusing constructability before materials hit the job site has become the new standard, while schedules are tighter, and scopes are increasingly complex.

Whether a large electrical contractor with in-house VDC resources or a smaller operation without a dedicated BIM team, the challenge is the same: scaling BIM capacity to meet growing needs. Yet, as expectations around BIM have grown, the shortage of skilled VDC personnel, especially large-scale commercial construction projects, has become more evident.

That’s why more contractors are looking to partner with 3rd party outsourcing for their electrical BIM services to keep pace and deliver install-ready models.

This blog will explore contractors’ challenges in these increasing resource demands, what makes outsourcing a strategic move, and who the right BIM partner might be.

Why Internal Teams Can’t Keep Up with Electrical BIM Demands

What’s often overlooked is that electrical scopes usually enter the MEP coordination process after mechanical and plumbing have already claimed space. This late involvement leaves often electrical trades scrambling to fit complex routing and equipment into increasingly limited zones without causing clashes or delaying prefab. As a result, the pressure to catch up, stay code-compliant, and maintain install quality is intense.

At the same time, it’s a tough task for contractors to retain the size of BIM teams needed to execute these projects as full-time employees when the demand is constantly changing. Many rely on generalists who juggle multiple scopes and lack deep, trade-specific knowledge, especially in electrical coordination. When deadlines tighten and field teams depend on precise models to guide installation, having the flexibility to scale up without long hiring cycles becomes a real advantage.

Outsourcing Electrical BIM Services: A Strategic Decision

Rather than being a last-minute fix, outsourcing has become a strategic choice for contractors who want to stay agile and competitive. Furthermore, having flexible access to electrical BIM expertise gives internal teams the bandwidth and precision they need to keep projects moving. In an industry where speed, precision, and prefab readiness are non-negotiable, outsourcing electrical BIM services gives contractors a critical edge.

Here’s what makes this shift a proactive, high-value decision:

1. Trade-Specific Coordination from Day One

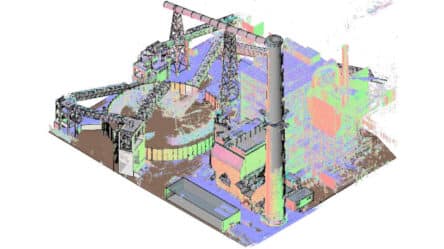

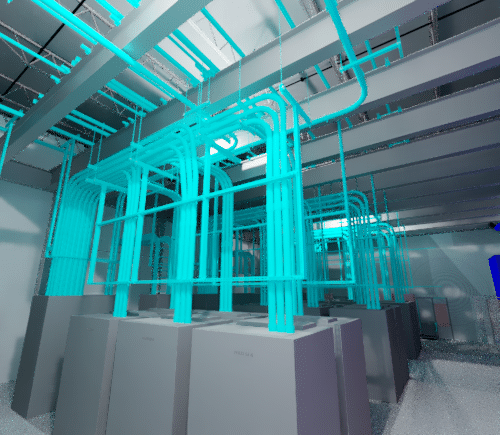

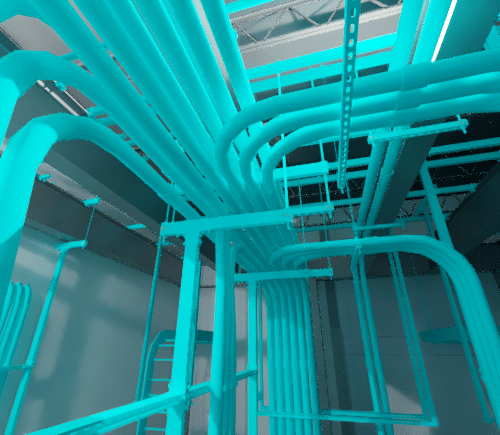

External BIM teams bring deep electrical expertise, from the National Electrical Code (NEC) to conduit routing, panel clearance, and installation sequencing. Their models are not just code-compliant; they’re constructible. That means fewer clashes, smarter layouts, and a smoother path to prefab and installation.

2. Instant Scalability and Faster Delivery

Outsourcing enables contractors to scale resources quickly, especially during peak coordination cycles. Teams like ENG offer ready-to-deploy specialists who can fast-track modeling without compromising quality, an essential advantage on prefab-heavy projects where delays in coordination stall fabrication.

3. Standardized, Install-Ready Deliverables

Partnering with external teams ensures consistent QA, centralized standards, and automation-driven modeling workflows. The result? Deliverables that go far beyond coordination: spool drawings for prefabrication, hanger layouts for early install planning, and Robotic total Station (RTS) points for the field. These are more than 3D models, they’re actionable tools your crews can rely on.

What Makes an Electrical BIM Partner Truly Valuable

Once you decide to outsource your electrical BIM scope, the next critical question is who you trust to deliver.

Not all BIM providers are created equal. Some offer general modeling support with limited trade depth. Others specialize in architecture or structure but lack the field knowledge required for accurate, install-ready electrical models. The right partner isn’t just fluent in software; they understand what success looks like on the job site.

Here’s what to look for:

- A team grounded in field realities

Look for BIM professionals who know when a routing decision will pass inspection, when a panel needs more clearance, and when a trade should adjust rather than hold its ground. Deep familiarity with the NEC is essential, but so is the judgment to apply it in tight coordination contexts.

- A culture of automation and process innovation.

Ask whether the team uses repeatable workflows or still relies on manual, one-off solutions. Strong partners leverage automation to reduce human error, speed up repetitive tasks, and keep your project moving. Whether generating spools, validating clearances, or batch tagging elements, smart automation frees up human focus for critical design decisions.

- Fluency across formats—not just Revit.

Today’s coordination environments are rarely 100% native. You might receive structural models in IFC, legacy elements in AutoCAD MEP, and equipment files in non-standard formats. A valuable BIM partner should integrate seamlessly with all of them. Ultimately, this bridges the gaps between tools and maintains model integrity.

- A proven quality control framework.

Before you receive any model or drawing, it should pass through an internal QA process. This includes clash checks, compliance reviews, prefab-readiness validation, and file cleanup. However, quality control also means delivering field-friendly documentation: models that are logically organized, easy to navigate, and annotated for layout, installation, and inspection.

Choosing a partner who brings this depth, structure, and accountability is not just outsourcing tasks. Instead, you’re taking a step toward a more efficient coordination workflow. This leads to better collaboration, fewer RFIs, and install-ready models that build as well as they look.

Conclusion:

In short, more contractors are extending their BIM capabilities through strategic partnerships in an industry defined by compressed timelines, evolving scopes, and a growing reliance on prefabrication. Outsourcing electrical BIM services is about meeting project demands with greater agility, precision, and confidence.

ENG partners with electrical contractors to help them scale smarter, move faster, and deliver with prefab in mind from day one.

Looking to streamline your electrical BIM workflow? Let’s talk.