Data centers demand high-performance infrastructure, especially when it comes to coordinating complex electrical systems. These mission-critical facilities often involve strict technical requirements, fixed routing constraints, and the need for speed and precision.

ENG’s Electrical BIM team was recently tasked with one such challenge on a large-scale data center project, where they needed to design conduit runs connecting outdoor Unit Substations (USS) to indoor Data Hall racks. In this case study, we’ll explore how ENG leveraged BIM for Data Center conduit coordination, delivering a constructible, scalable, and prefab-ready solution through modular planning, close client collaboration, and advanced detailing strategies.

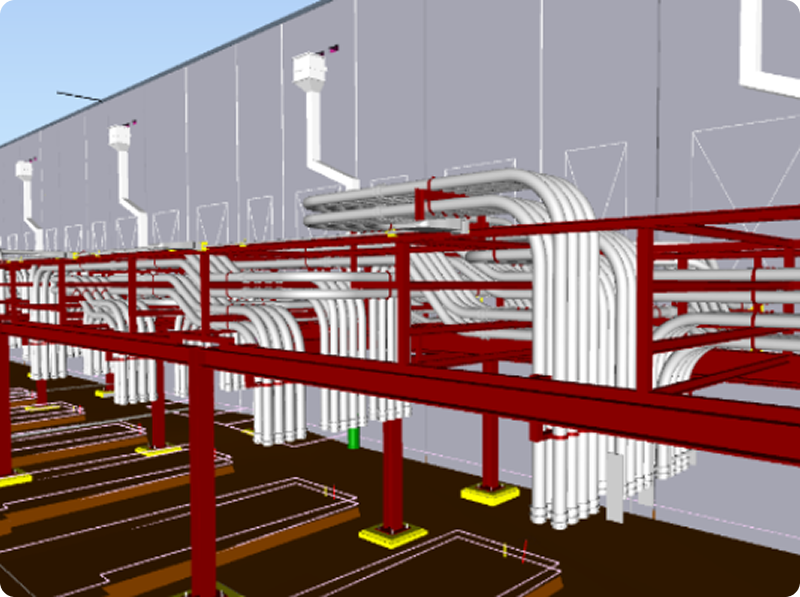

One of the project’s most complex aspects was designing the conduits to run from the exterior to the interior of the data center without clashing, considering fixed entry and exit positions.

In parallel, ENG’s team collaborated with the manufacturing company to propose, adjust, and validate the supporting structure that would carry the conduits throughout the building. As a result, these constraints created a high coordination complexity requiring precision and flexibility.

Given the size and scale of the installation, spanning the entire Data Hall, and the fact that prefabrication can take longer than the initial modeling effort, ENG began by designing the modules from the ground up. Key considerations included:

Consequently, starting from scratch ensured the model was fully constructible and aligned with both fabrication and field installation needs.

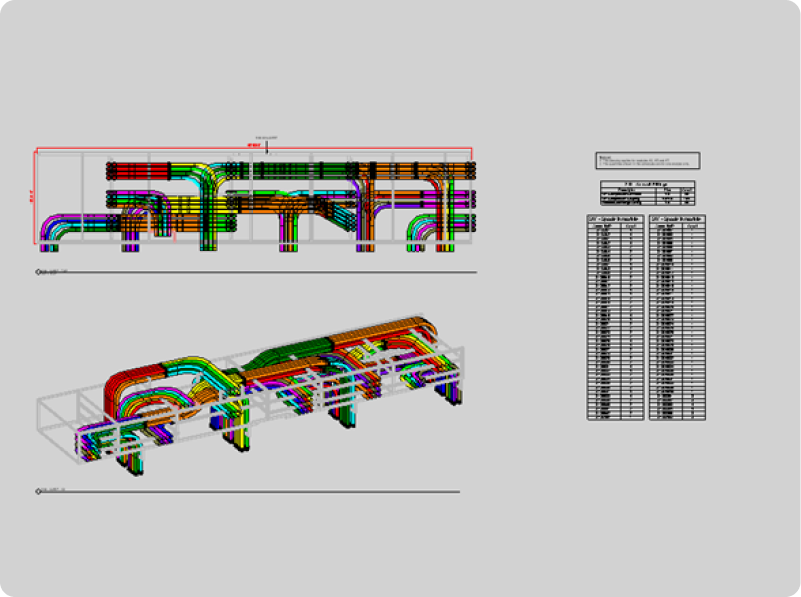

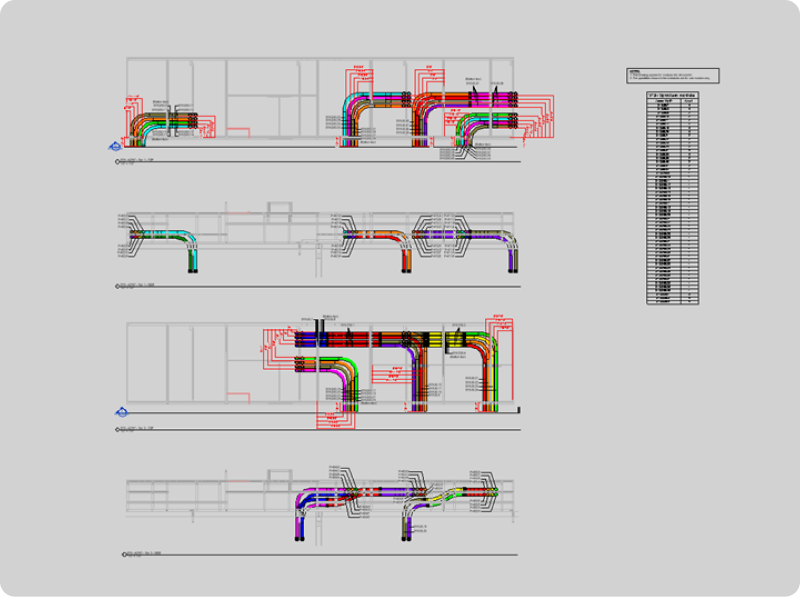

ENG used a modular BIM layout to simplify design and speed up fabrication. Furthermore, the electrical team standardized conduit modules that were reused throughout the design wherever possible. Additionally, when adjustments were necessary due to field constraints, they were kept minimal, preserving consistency and reducing the volume of one-off details. This approach enabled:

Optimizing spool design was key in improving field installation and reducing labor hours. ENG’s Electrical BIM team strategically placed couplings along conduit runs to keep spool lengths under 20 feet. This also helped avoid bends that could complicate handling during installation.

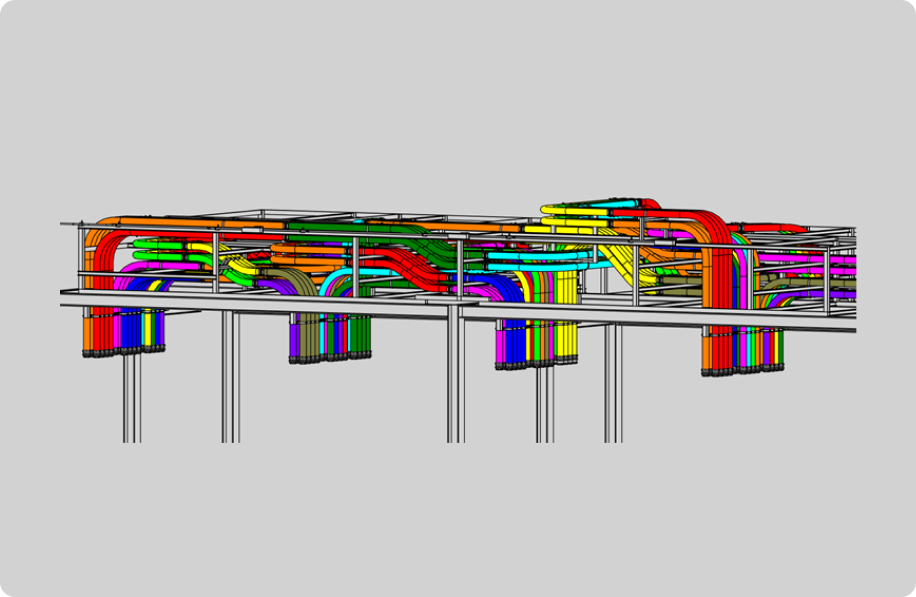

ENG assigned an ID to each unique spool and visually differentiated using color coding in the BIM model. Through the arbitrary assignment of colors associated with the name of each spool and a filter system developed withing each template, the electrical BIM team helped field teams quickly identify which spools were identical or unique. This minimized errors and sped up installation.

Ongoing communication was essential for success. ENG conducted daily BIM coordination meetings with the client to ensure constant alignment. These sessions allowed the team to:

The outcome was a highly responsive process that preserved design intent while adapting quickly to evolving field constraints.

ENG took a proactive approach to coordination and standardization. This led to significant reductions in production time, cost, and complexity.

Results included:

The combination of modular design, color-coded spools, and constant collaboration made delivering technically complex conduit modules feasible under demanding conditions.

Ultimately, this project shows how strategic BIM implementation, prefab thinking, and close client collaboration can simplify even the most technically demanding conduit assemblies. By designing from scratch, standardizing with modular logic, optimizing prefab, and maintaining daily alignment with stakeholders, ENG delivered a group of modules that were both buildable and repeatable and efficient to fabricate and install.

As data centers grow in complexity and scale, BIM for data center conduit coordination will remain a critical enabler of smarter infrastructure, transforming the way in which the electrical discipline is designed, documented, and delivered.

Sign up here to get the latest BIM news and tips, as well as ENG updates.