BIM coordination in MEP projects is designed to align trades, validate constructability, and reduce field conflicts before installation begins. However, what happens when coordination gradually turns into redesign? As a result, redesign involves major modifications that change the design intent, such as relocating equipment, re-routing entire systems, or modifying layouts due to fundamental design gaps or site conditions. Redesign often adds scope, time, and cost. Challenges that are quite familiar to many GCs and MEP contractors

In this article, we’ll define what BIM coordination entails, how to recognize when coordination is crossing into redesign territory, why it occurs, and what steps teams can take to prevent it.

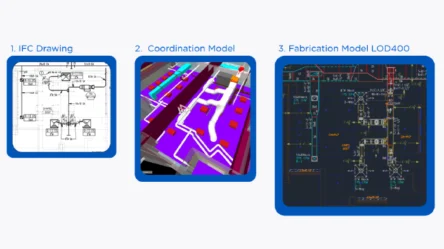

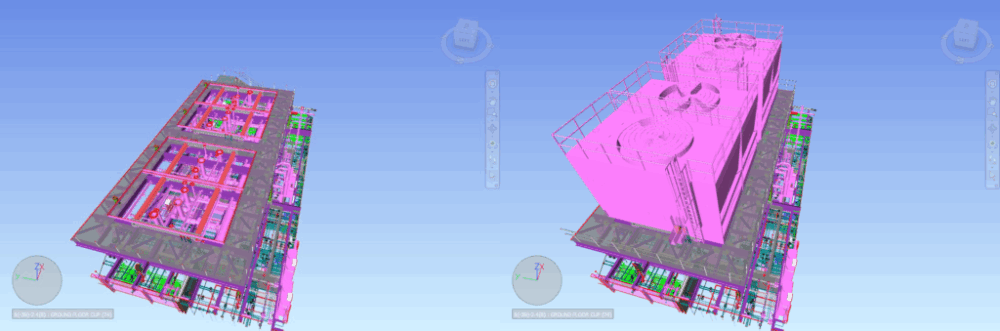

What True BIM Coordination Involves

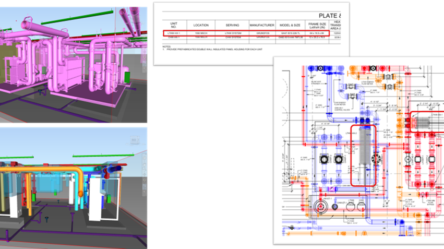

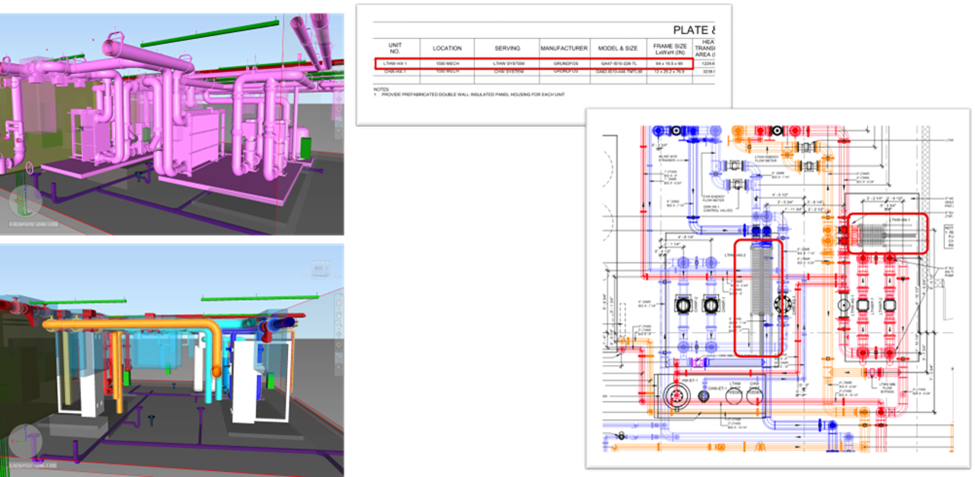

BIM coordination should address minor adjustments that ensure systems fit together and meet constructability requirements. Yet, substantial changes, like relocating Fan Coil Units (FCUs) out of hallways due to overcrowding or redesigning entire mechanical rooms because of clearance issues, often signal deeper design gaps.

Beyond design conflicts, contractual wording can also create confusion about responsibilities. For example, when substantial scope changes such as relocating equipment or redesigning rooms are labeled as “coordination,” MEP contractors may absorb costs that should fall to the design team.

Why Coordination Turns into Redesign

The challenges described above, from major layout changes to unclear responsibilities, often stem from deeper issues that begin early in a project. As a result, two recurring problems frequently blur the line between coordination and redesign:

1. Vague contract language

Phrases like “coordination as required” seem harmless but can unintentionally shift design responsibilities to trades, forcing them to absorb work beyond their scope.

2. Assumptions made early in design

Coordination challenges frequently stem from placeholder data or incomplete specs rather than modeling errors.

How to Plan Early to Avoid Redesign

Engaging field teams and installers before modeling begins can avoid many redesigns. However, early input ensures that space, clearance, and access requirements are well understood, reducing surprises later.

Another practical tip is to use simple PDF overlays early in the project. This helps identify high-risk areas and narrow the focus before full modeling begins. Ultimately, incorporating real equipment data as soon as possible helps coordination efforts stay accurate and efficient.

How to Set Boundaries Through Documentation

Even with proactive planning, changes are inevitable. That’s why defining what qualifies as coordination vs. redesign upfront is critical. A simple rule is that if a system moves to a different room, it’s a redesign, not coordination.

Clear documentation, through RFIs, meeting notes, and version tracking helps teams track decisions and prevent scope creep, ensuring that minor adjustments do not escalate into large-scale redesign or rework.

Want to Learn More?

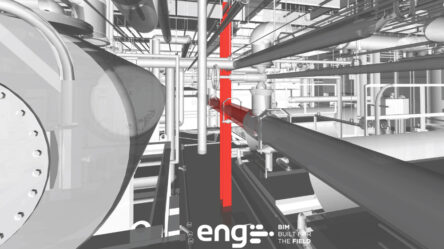

This topic was first explored during the last presentation at the Advancing Preconstruction event in San Diego and then expanded on in a recent webinar hosted by Jay Berryhill (CRO at ENG). Joined by Chris Turney (EVP at All Trades Mechanical) and Antonio Gutierrez (BIM Coordinator at ENG). The panel shared real-world project examples and strategies to clearly define responsibilities, improve collaboration, and reduce costly redesign.

Watch the full Webinar on BIM coordination vs. redesign here.