Industrial facilities are complex and expensive to operate. When information is outdated or inaccurate, it can impact safety, production, and investment decisions. However, many owners rely on drawings that no longer accurately reflect current conditions, thereby increasing the risk during renovations, expansions, and maintenance work.

3D laser scanning provides an accurate, up-to-date digital record of existing conditions, while some areas may require brief access restrictions or minor operational interruptions, these can be coordinated in advance to align with the facility’s normal operations, allowing owners to plan and manage projects with confidence.

This guide explains what 3D laser scanning is, when it should be used, and how it delivers measurable value for industrial facility owners and operators.

What Is 3D Laser Scanning in Industrial Facilities?

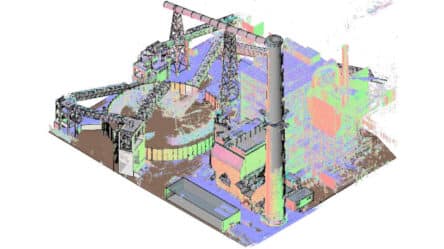

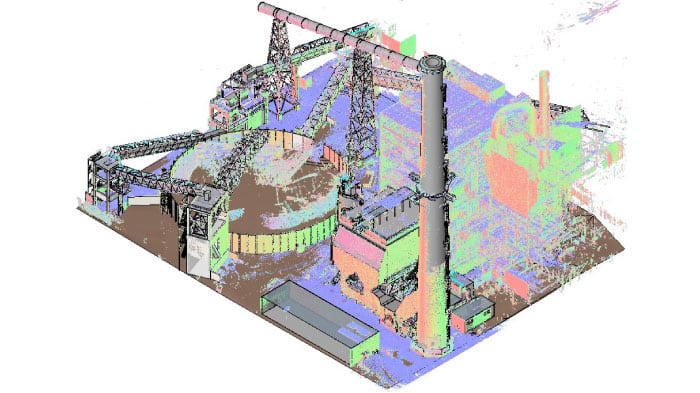

3D laser scanning is a non-contact reality capture method that uses laser pulses to collect millions of precise spatial data points. These data points form a 3D point cloud representing the true measurable geometry of buildings, structures, equipment, and layouts.

In industrial facilities, project teams commonly use laser scanning to document:

- Building structures and floor layouts

- Mechanical and electrical equipment

- Piping systems and process infrastructure

- Hard-to-reach or dangerous areas

The resulting data can be used directly for design, engineering, construction planning, facility management, and long-term asset and architectural documentation.

Why Accurate Facility Data Matters for Industrial Owners

Outdated or Missing As-Built Documentation

Many industrial facilities have evolved over decades of continuous modification and expansion. Teams replace equipment, change processes, and make modifications without consistently updating drawings. As a result, owners often face:

- Incomplete or inaccurate layouts

- Lost or unreliable legacy documentation

- Increased reliance on assumptions during planning

These gaps create uncertainty and elevate risk during renovation or expansion projects.

Operational Downtime and Financial Impact

In industrial environments, downtime is costly. Poor facility data can lead to:

- Delays during construction or installation

- Unplanned shutdowns caused by unforeseen conflicts

- Costly change orders and rework

Accurate existing-condition data enables projects to be planned properly before work begins, thereby reducing surprises that impact production.

Safety and Compliance Considerations

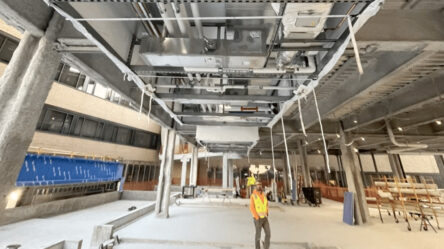

Industrial facilities often contain confined spaces, elevated equipment, and complex systems. Traditional measurement methods require personnel to access these areas physically, increasing exposure to risk. Reliable spatial data also supports:

- Safer planning of maintenance and upgrades

- Better hazard identification

- Improved readiness for audits and inspections

When Should Facility Owners Use 3D Laser Scanning?

Facility owners should consider 3D laser scanning whenever decision-makers require accurate, current and precise data, particularly in operational environments

Common scenarios include:

- Planning renovations or retrofits in active facilities

- Expanding production lines or installing new equipment

- Verifying existing conditions before design or construction

- Creating or updating facility documentation

- Supporting long-term capital planning and asset management

Laser scanning is especially valuable when drawings are missing, outdated, or unreliable.

Key Benefits of 3D Laser Scanning for Industrial Facility Owners

Accurate As-Built Documentation and Verification

Laser scanning captures the facility exactly as it exists. This creates a reliable “single source of truth” that owners can use across multiple projects and disciplines. Accurate data reduces guesswork and improves decision quality across all project phases

Minimal Disruption to Ongoing Operations

As laser scanning is non-contact, data can typically be captured while facilities remain fully operational. This minimizes or eliminates the need for shutdowns, allowing owners to maintain productivity while collecting critical information.

Reduced Project Risk and Better Planning

With accurate existing-condition data, project teams can:

- Identify constraints early

- Resolve design conflicts before construction

- Reduce orders and delays

This proactive approach lowers overall project risk and improves cost predictability.

Long-Term Value for Facility and Asset Management

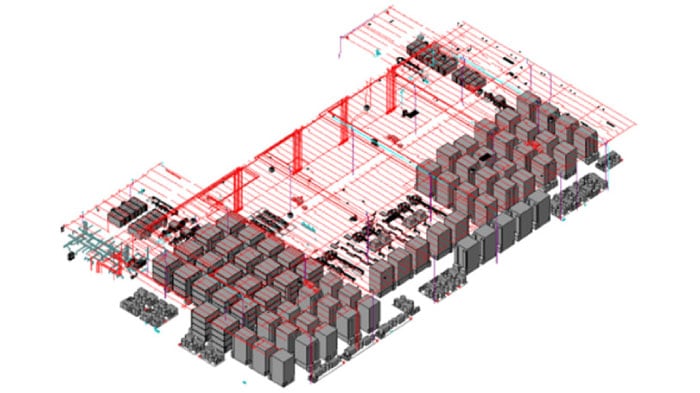

Scan data can be reused long after a single project is complete. Owners often leverage laser scanning to:

- Create digital facility records

- Support maintenance and asset tracking

- Develop digital twins for long-term planning

Over time, this data becomes a strategic asset rather than a one-time deliverable.

Practical Applications for 3D Laser Scanning in Industrial Facilities

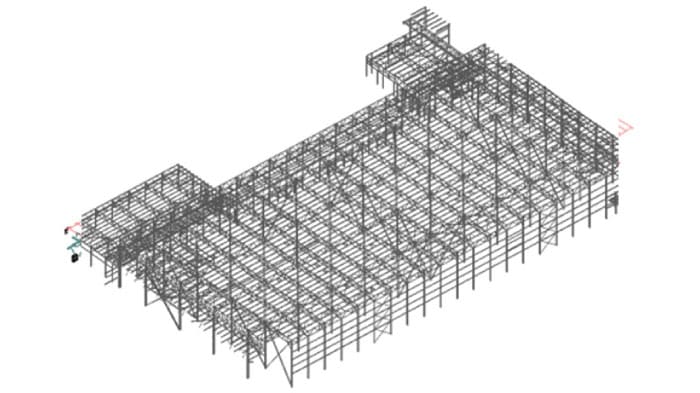

Design and Construction Planning

Laser scans provide accurate base data for engineers and designers, allowing new designs to be developed within real-world constraints. This improves coordination across teams and reduces downstream conflicts during construction.

Facility Management and Asset Management

Accurate spatial data supports better facility oversight. Owners can centralize information about layouts, equipment locations, and access routes, improving maintenance planning and response times.

Safety, Risk Assessment, and Compliance

Scanned models allow stakeholders to identify hazards, evaluate access conditions, and plan safety measures without physically entering high-risk areas. The data can also be used for virtual walkthroughs and training.

Retrofitting and Renovation Projects

When upgrading or modifying existing facilities, laser scanning enables owners to accurately assess structural conditions, space availability, and system clearances. This reduces uncertainty and helps projects move forward efficiently with minimal operational impact.

3D Laser Scanning vs Traditional Surveying Methods

| Aspect | Traditional Methods | 3D Laser Scanning |

| Accuracy | Variable | High and consistent |

| Speed | Slow | Rapid |

| Operational Disruption | Often required | Minimal |

| Safety | Physical access needed | Non-contact |

| Data Reusability | Limited | High |

Traditional methods can still serve basic needs, but they struggle to meet the accuracy, safety, and efficiency demands of modern industrial facilities.

Best Practices for Owners Implementing 3D Laser Scanning

- Define clear objectives before scanning begins

- Capture data before design decisions are finalized

- Treat scan data as a long-term facility resource

- Integrate results into existing facility management workflows

- Engage all stakeholders early to ensure alignment

Final Thoughts

For industrial facility owners, 3D laser scanning is far from being a technical upgrade. Instead, it is a risk management and planning tool. When providing accurate, up-to-date facility data without disrupting operations, laser scanning enables safer projects, stronger financial outcomes, and long-term asset value.

Planning Renovation, Expansion, or Facility Upgrade?

Accurate existing-condition data is the foundation of successful industrial projects. 3D laser scanning provides the clarity needed to plan with confidence and minimize operational risk.

Interested in implementing 3D laser scanning solutions for your next project?

Get in touch with us today to see how we can help!