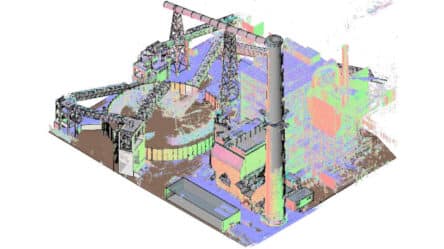

Building Information Modeling (BIM) has become indispensable for mechanical & plumbing contractors delivering medium and large-scale projects. Through Mechanical and Plumbing BIM services, teams can connect to every stage of the project lifecycle, combining 3D geometry and data-rich intelligence to enhance coordination, fabrication, and field performance.

This integrated process creates a single source of truth that unites project teams, supports prefabrication planning, and minimizes costly rework. Overall, BIM provides a clear competitive advantage in the AEC industry, where precision, coordination, and timely execution define profitability.

The Business Impact: Why BIM Matters for M&P

For mechanical and plumbing contractors, the value of BIM goes far beyond 3D coordination. When approached with constructability in mind, the model becomes a real-time decision-making tool that supports prefabrication, sequencing, and field installation.

A well-coordinated BIM process improves visibility across trades, helping teams plan installations with confidence, avoid costly redesigns, and keep projects on schedule.

As German Siegrist, ENG’s Mechanical & Plumbing VDC Director, explains:

“Learning from ENG’s experience, having a highly detailed and well-coordinated model that captures even the smallest details ensures that field teams can execute their work efficiently and confidently.”

Defining the Scope of Mechanical & Plumbing Services

Mechanical BIM Services

Mechanical services include designing, modeling, coordinating, and installing systems that maintain thermal comfort and indoor air quality. This scope typically covers:

- Air systems: Air-handling units, Rooftop units, duct systems, air terminals, fans, dampers, etc

- Piping systems: Hydronic, Refrigerant, steam, condensate, etc.

- Mechanical equipment: Boilers, chillers, heat exchangers, pumps, tanks, etc

- Controls: thermostats, sensors, valves, etc

BIM models these elements to fabrication-level accuracy, enabling inter-trade coordination and reliable prefabrication and installation planning.

Plumbing BIM Services

Plumbing covers the design, modeling, coordination, and installation of systems for water supply, waste removal, and fluid management, including:

- Water supply and distribution: cold/hot water lines, pumps, heaters

- Drainage and vent: sanitary, waste, and storm systems

- Specialty systems: fire suppression, gas piping, medical gases (where applicable)

- Fixtures: toilets, sinks, pumps

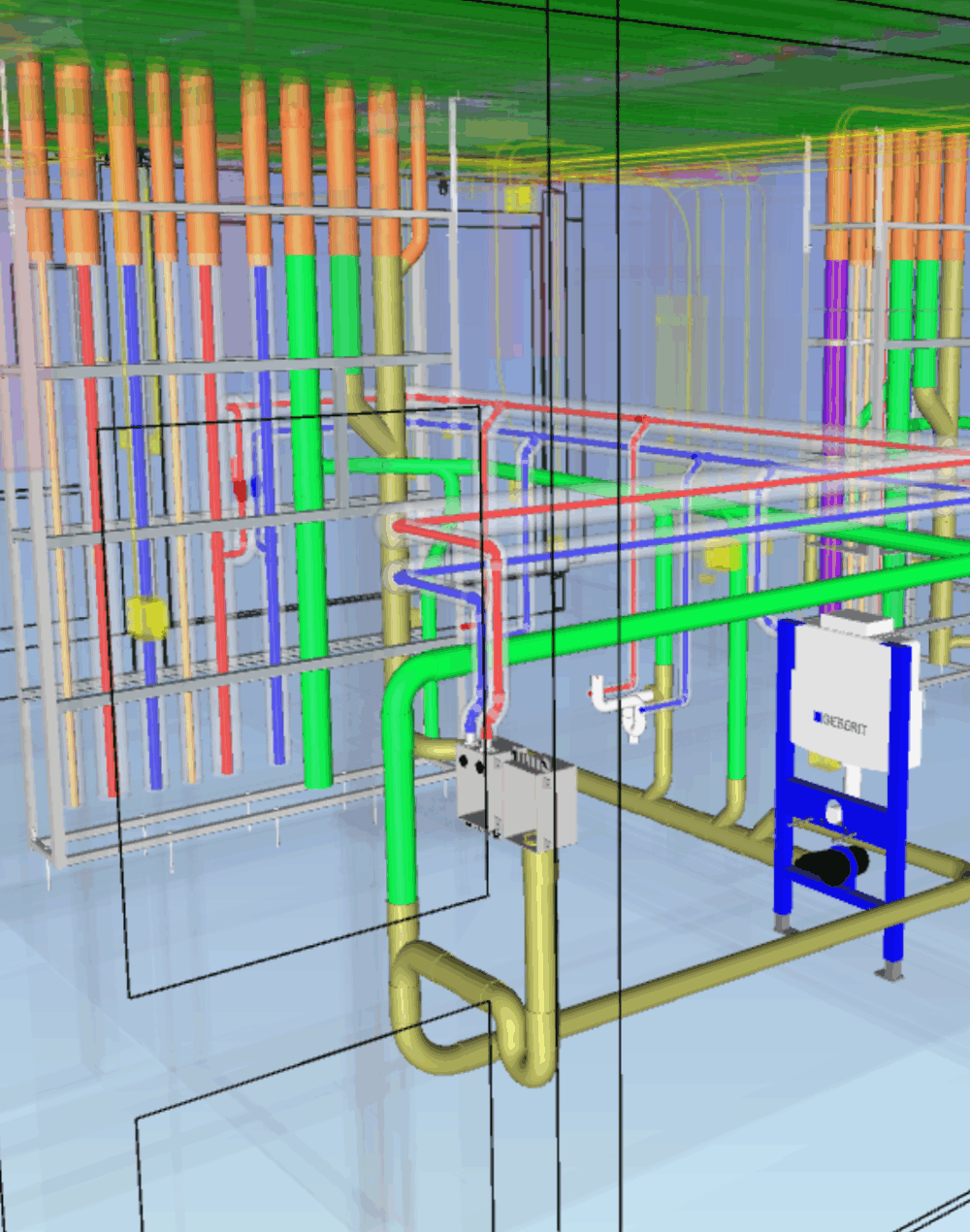

BIM ensures spatial alignment with architectural and structural elements so clashes are resolved digitally before materials are fabricated.

Typical BIM Deliverables for M&P Contractors

Deliverables function as design validation and construction-ready assets, ensuring every modeled element can be built, installed, and maintained as intended. These include:

- Coordinated 3D BIM models (discipline-specific and multi-trade)

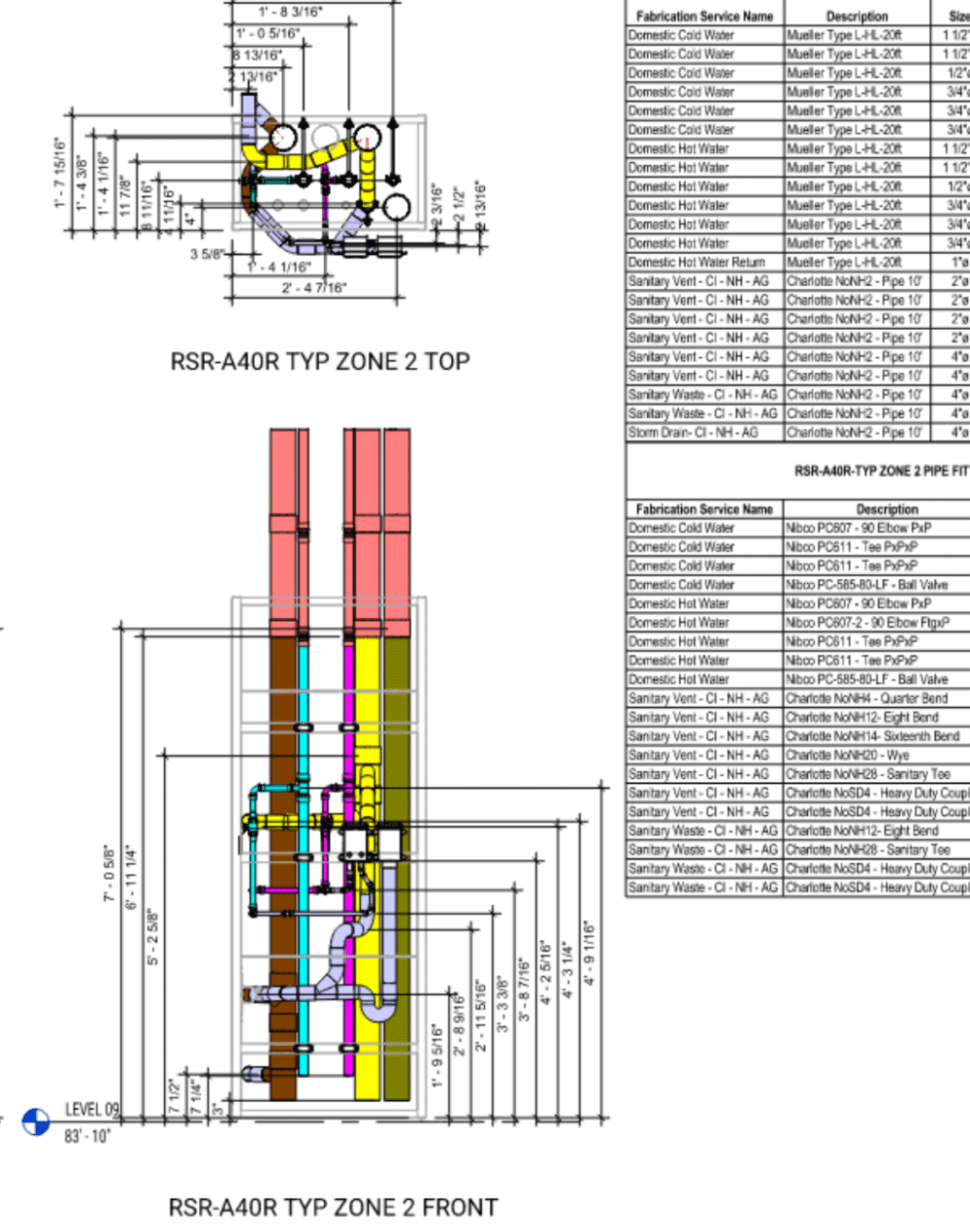

- Shop drawings for fabrication and installation

- Sleeve and hanger layouts with field-ready dimensions

- Spool sheets and equipment schedules to sequence prefab and install

- As-built models and documentation reflecting field adjustments

With LOD 350/400 models, spool sheets, and coordinated sleeve/hanger layouts, contractors can shift critical scope to off-site fabrication and use model-driven layout tools to install confidently.

How BIM Supports Prefabrication and Modular Construction

BIM enables off-site fabrication by turning digital coordination models into fabrication-ready shop drawings. At advanced Levels of Detail (LOD 400 and above), MEP systems can be modeled as complete spools and assemblies—including all fittings, supports, and connection points. These assemblies can then be manufactured in controlled environments, improving precision, quality, and installation speed.

As Alvaro Enet, ENG’s BIM Specialist, explains, “Because these models are fully coordinated across disciplines, prefabricated modules fit seamlessly on-site, reducing rework, installation time, and material waste.”

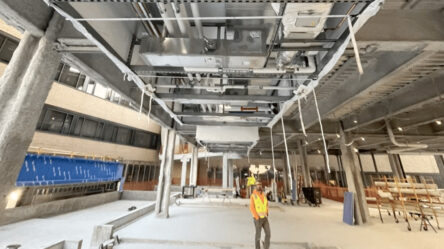

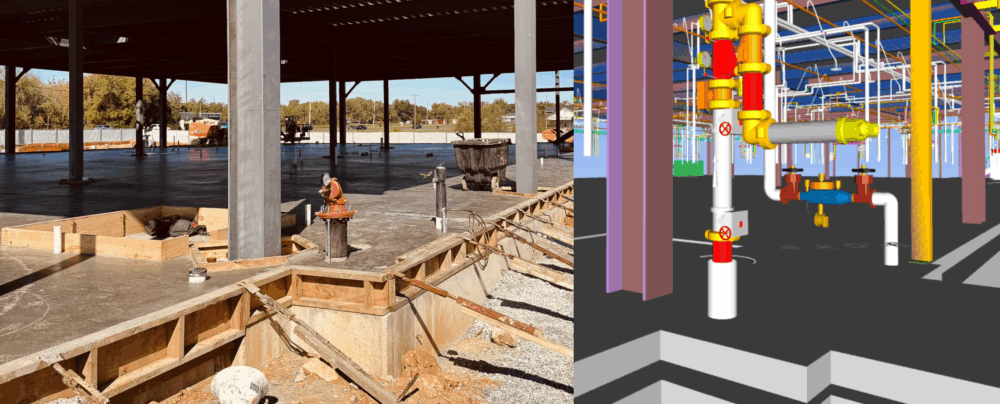

BIM also serves as a bridge between Virtual Design and Construction (VDC) and field layout. Using technologies such as total stations, GPS-enabled tools, and robotic survey equipment, data from the coordinated model is transferred directly to the field. This connection ensures that every prefabricated assembly is installed exactly as designed.

With this continuous feedback loop, where verified as-built data returns to the model, contractors maintain full alignment between digital intent and site reality, driving more predictable outcomes.

Common BIM Challenges, and How M&P Contractors Overcome Them

Even with robust coordination workflows, mechanical and plumbing contractors frequently encounter three recurring challenges: design-to-field mismatches, change orders, and coordination delays. BIM directly addresses each of these pain points.

- Design vs. Field Mismatch: BIM provides a shared 3D coordination model that integrates architectural, structural, and MEP disciplines into one environment. This unified approach eliminates discrepancies between design drawings and real-world construction conditions, ensuring that fabrication and installation follow accurate, up-to-date information. As a result, field teams spend less time resolving conflicts and more time executing efficiently.

- Change Orders: With real-time model updates and clash detection, BIM identifies design conflicts early—long before materials reach the jobsite. This proactive visibility helps contractors minimize costly and time-consuming change orders during construction. By aligning every stakeholder around current data, teams can adapt quickly to design revisions without disrupting schedules or budgets.

- Coordination Delays: BIM fosters cross-discipline collaboration through a centralized, cloud-based model that serves as a single source of truth. Because all trades work from the same coordinated data set, communication gaps are reduced, approvals move faster, and coordination meetings become more productive. The result is smoother project delivery and improved schedule reliability.

Conclusion: Building a Constructible Future with MEP BIM

For mechanical and plumbing contractors, adopting BIM workflows built around constructability transforms every stage of the project’s lifecycle. By integrating accuracy, collaboration, and data intelligence, MEP BIM modeling delivers measurable gains in quality and profitability.

At ENG, our team bridges VDC and field execution, helping contractors implement BIM processes that reduce risk, improve installation speed, and ensure every model is truly build-ready.

Interested in learning how ENG’s BIM experts support M&P contractors? Explore our Mechanical & Plumbing BIM services or consult our team.