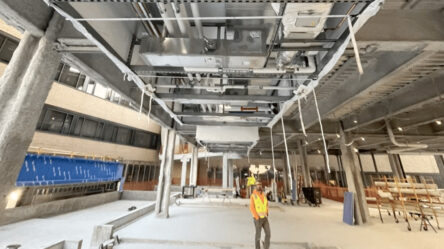

With tighter schedules and ongoing labor shortages, MEP contractors can’t afford mistakes in BIM.

A single misstep, like a misaligned duct penetration, an overlooked specification, or an overcomplicated layout, can derail installation, drive up costs, and erode trust.

In this article, ENG highlights the five most common MEP BIM mistakes and how to avoid them, drawing on real project experience and insights from Bill DeCarlo, ENG’s BIM Technical Lead

MEP BIM Mistake #1: Drawings Non-Compliant with Specifications and Details

One of the most frequent mistakes in MEP BIM is producing drawings without first carefully revising project specifications and details. These documents outline insulation requirements, static pressure ratings, and fabrication. Consequently, they must be read and interpreted before drafting begins to avoid errors downstream.

How to avoid it: Once this interpretation is complete, it is best to share a summary with the client for confirmation. According to Di Carlo, requesting confirmation ensures all parties align early. This simple step reduces assumptions and avoids rework later in the project.

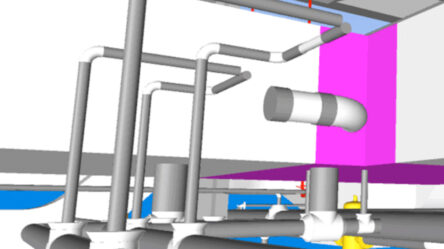

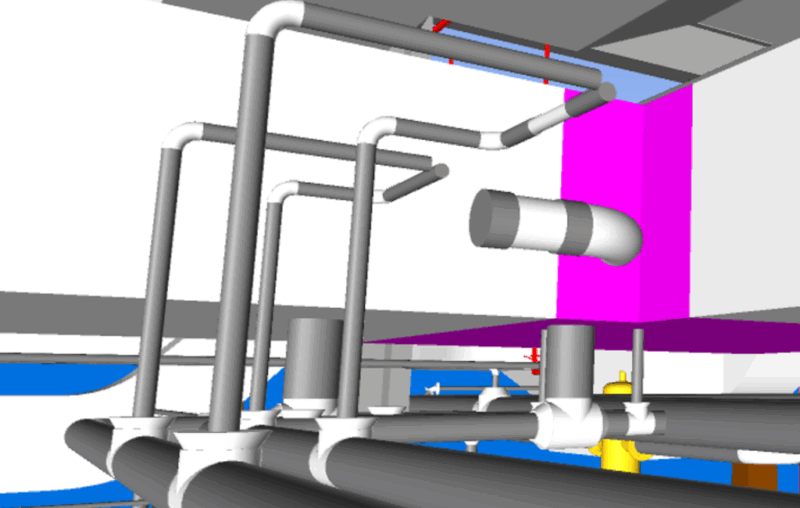

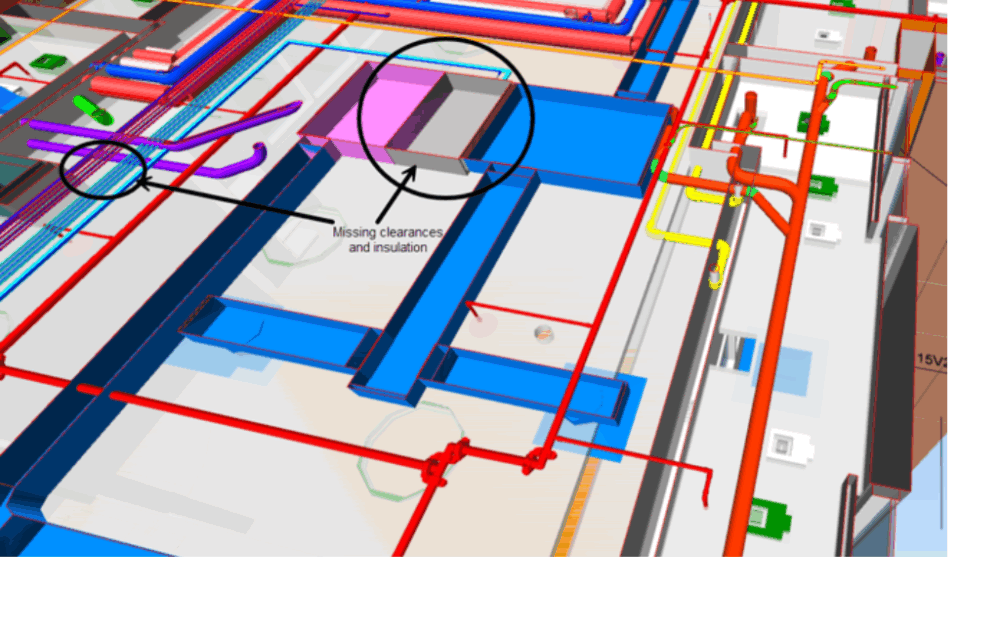

MEP BIM Mistake #2: Incorrect Penetration Information in Slabs and Roofs

Another common error in MEP BIM occurs when teams lay out holes for equipment or fire dampers without the proper submittal. Sleeves in slabs and roofs need to be sized to match the ducts, fire dampers, or equipment being installed, and the gaps must also allow for insulation, curb openings, or fire damper heads. Overlooking these details often leads to inaccurate openings and unnecessary rework.

How to avoid it:

- Base openings on approved submittals, not assumptions.

- Clearly note that sleeve dimensions reference the inside edge of the curb.

- Confirm with the customer whether fire dampers should align with inside or outside duct dimensions, as this decision drastically impacts sleeve sizing.

MEP BIM Mistake #3: Overusing Fittings and Nonstandard Cut Pieces

Excess fittings and nonstandard cut pieces are common sources of inefficiency in MEP BIM. When systems are modeled with too many nonstandard components, whether ducts, pipes, or conduit, the result is higher costs and longer lead times. Consequently, every piece that falls outside of standard fabrication methods often requires additional manual work, slowing down production and introducing opportunities for error.

How to avoid it: Designing with standard lengths and minimizing custom fittings streamlines fabrication, reduces waste, and supports smoother installation. As DeCarlo notes, fewer nonstandard pieces improve both efficiency and cost control.

MEP BIM Mistake #4: Making Assumptions Instead of Submitting RFIs

Another recurring BIM pitfall occurs when unclear specifications or incomplete drawings lead teams to make assumptions rather than seek clarification. This often results in errors that surface late in the project.

How to avoid it: Submit RFIs as soon as ambiguities are identified. Highlight the specific sections or details in question and request clarification early. Proactive communication saves time and avoids costly rework down the line.

MEP BIM Mistake #5: Relying Only on the Model and Ignoring Architectural, Structural, and Mechanical Drawings

Design teams frequently include disclaimers noting that their models may not always reflect the most current information. Structural steel, joists, or equipment may change without being updated in the federated model. Relying solely on the model, without checking against contract drawings, can create significant field conflicts.

How to avoid it: Always cross-check the model against architectural, structural, and mechanical drawings to ensure accuracy. When discrepancies appear, submit an RFI. Contract drawings and specifications remain the final authority over models.

Conclusion

In summary, the five most common MEP BIM mistakes– skipping specification reviews, misaligned slab and roof penetrations, overusing nonstandard fittings, relying on assumptions instead of RFIs, and trusting the model without drawings—can all be avoided with better review, proactive communication, and standardization. By preventing these errors, contractors reduce rework, keep projects on schedule, and maximize success.

ENG helps contractors avoid these BIM mistakes with build-ready models, proven workflows, and expert support. Contact our team to learn more.